@Thermal accumulation material is composed of PCM (phase change material) and Micro-capsule material. Paraffin which has large potential heat amount is used as PCM. We have two different kind of micro-capsule wall materials. One is Melamine type and another is Non-formaldehyde type. These micro-capsules are viscous white color slurry in appearance. Viscous Gel as well as Powder products are also available.

The advantage and character of Thermal accumulation micro-capsule is that it can repeatedly absorb and emit heat energy. The paraffin in the micro-capsule absorbs and emits gthe potential heat energyh when it inverts from solid to liquid phase and from liquid to solid phase. The paraffin absorbs the gheat of fusionh, when solid phase melts into liquid phase by heating. The paraffin emits the gheat of solidificationh, when liquid phase solidifies into solid phase. This is the basic mechanism of Thermal accumulation of warm & cool action. The temperature of thermal accumulation of absorption and emission can be adjustable with change of melting temperature of paraffin as core material of micro-capsule.

CHARACTER & APPLICATION OF MICRO-CAPSULATED THERMAL ACCUMULATION MATERIAL Micro-capsulated thermal accumulation material has a wide and potential application possibilities with various different temperatures. It is possible at the option of the kind of PCM (paraffin) to be required temperature and also possible to develop the new product having temperature buffering property to be required certain temperature. For example, 5 type can accumulate the temperature at 5 even if the heating temperature rises more than that. On the contrary, even if the heating temperature go down at less than 5, it works to keep its temperature at 5. The conventional cooling material goes up its temperature when the heating temperature rises. However, Micro-capsulated Thermal accumulation material can keep its temperature at fixed of 5 for a certain period of time.

DESIGNED TEMPERATURE & APPLICATION EXAMPLE: [PCM melting point at 4]

THE LIST OF MICRO-CAPSULATED THERMAL ACCUMULATION MATERIALS

The character of Micro capsulated Thermal accumulation material

Evaluation method of the performance PjMeasuring by Thermography and Thermometer: Thermo-camera and Thermometer are very effective evaluation method and tool to measure the performance of quality of the finished products. Its measuring methods depend upon the kind of materials or form of substrates. The proper measuring method will be advised by our technical team upon request. QjDifferential thermal scanning count (D S C) Few ten gram of micro capsulated material its self or its finished fabrics can be measured for heat energy amount. The below is the measuring example of PMCD-25. Obtainable information by this measuring. Through this chart, the range of temperature of melting and solidification point can be obtainable. In this measuring, melting point at 26.2 and solidification point at 24.8.@ Amount of potential heat of fusion SXDTTi^@ Amount of potential heat of solidification |TODSRi^ By the repeating tests, the durability of capsulation performance can be measured. [ Measuring device:@Seiko instruments crbQQObt ]

Measurement of surface and inside temperature of fabrics By Thermo-graphy and Thermometer.

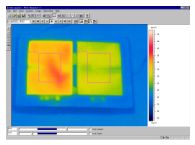

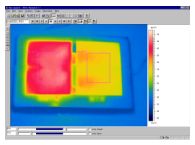

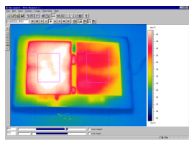

Heat the test-specimen by infrared light lamp (Kett 400w) with the distance of 40cm from the fabrics. Take the thermo-graph picture by thermo-camera with every 1 minute. At the same time, Inside of fabric temperature is also measured by thermo-sensor. Prepared 2 test specimens fabrics and thermal-sensor inserted between two fabrics.

MEASURED RESULTS: PMCD-32NF (non-formaldehyde type ) is treated on 100% polyester fabrics. The temperature of surface of fabric is measured by Thermography and the temperature of inside of fabric is measured by Thermo-sensor. The difference of temperature of surface of fabrics are observed after 1 minute later of infrared heating and the treated fabrics temperature does not rise. Besides, the temperature drop of treated fabric is slower than non-treated fabric after cooling down. The data of fabric surface temperature change and its inside temperature change is made into graph with repeated heating and cooling at three times. It has been proven that thermal accumulation performance is achieved even after heating and cooling. @@Thermo-camera picture : heating after 2 minutes  @@Just after heating started

Addition to Gel type Thermal accumulation material

Measure the temperature change of Sealed pack GEL by changing the temperature of Circumstances. As comparison, test the two difference test specimens. One is conventional transparent gel and another is gel containing 50% of PMCD-25 ( 25 TYPE ). Measuring device: Thermo-Printor AP - 320 ( Adachi measurement made ) Test method: Measure the temperature of Gels by thermal-sensor. Keep the Gels over night at Room with constant temperature at 20. Then, Heat them at 37@ And cool down at room temperature of 20 ~ 18 repeatedly. Test results: Temperature change data and graph is as per attached. The conventional Gel changes its temperature with the change of outside temperature. While, the change of temperature of Gel containing 50% of PMCD-25 is very small at around 25area. This is proven data of good performance of Thermal accumulation material.  Addition to Concrete Block

Prepare the concrete containing 30% of PMCD-15 and compare with conventional concrete. Measure the change of surface temperature of concrete by changing the temperature of outside circumstance. Measuring device: Thermo-Printor AP - 320 ( Adachi measurement made ) Test method:

Test results:

Addition to non-woven sheet

Observe the temperature change of heated sheets. Measuring device: Thermo-camera by Nippon Electric made Model JTG-6200 Test method: Keep them at room temperature at 20 Test results: Non woven sheet containing thermal accumulation material does not drop its temperature on compared with non-woven sheet blank without addition.

|