[TECHNICAL INFORMATION]

RECYCLING PET MODIFIER

AR-P-1100

Introduction

PET bottle recycling has been a focus of attention in recent years in accordance

with increasing demand for PET with its versatile character, and enforcement

of The Containers and Packaging Recycling Law (Japan) in 1997. Collection

of used PET bottles (recycling PET) has been then increased every year

as shown in the table 1 below.

Table 1. Collection of used PET bottles

Municipalities Collection Municipalities Collection |

Sep. 2005

Japan PET Bottle Association |

| @@ |

Volume of collected

bottles(ton) |

Production

(ton) |

Rate of collection

(%) |

| 1995 |

2,594 |

142,110 |

1.8 |

| 1996 |

5,094 |

172,902 |

2.9 |

| 1997 |

21,361 |

218,806 |

9.8 |

| 1998 |

47,620 |

281,927 |

16.9 |

| 1999 |

75,811 |

332,202 |

22.8 |

| 2000 |

124,873 |

361,944 |

34.5 |

| 2001 |

161,651 |

402,727 |

40.1 |

| 2002 |

188,194 |

412,565 |

45.6 |

| 2003 |

211,753 |

436,556 |

48.5 |

| 2004 |

238,469 |

513,712 |

46.4 |

Total Collection Total Collection |

| @@ |

Volume of collected

bottles(ton) |

Production

(ton) |

Rate of collection

(%) |

| 2001 |

177,186 |

402,727 |

44 |

| 2002 |

220,256 |

412,565 |

53.4 |

| 2003 |

226,405 |

436,556 |

61 |

| 2004 |

319,893 |

513,712 |

62.3 |

Remarks :

Production is weight of Recycling designated PET bottles@(soft drinks,

soy sauce and liquors) |

|

Recycling PET was mainly reused as fibers and sheets as shown in the table

2. It is because such characteristics of recycling PET limited applicable

molding method as the molecular weight reduction in molding where the melt

viscosity might be decreased, and an extreme decrease in the impact strength

without drawing. Fibers and sheets made by recycling PET, however, saturated

the market already, so that the most of collected PET bottles began to

be thrown out before recycling.

Under such circumstances, development of applicable method of injection

and profile extrusion molding has been an essential issue for recycling

PET.

Table 2. Trend of recycled PET's market capacity in Japan

Sep. 2005

unit : thousand tons |

| Market |

1997 |

1998 |

1999 |

2000 |

2001 |

2002 |

2003 |

2004 |

| Fibers |

6.1 |

16.9 |

25.2 |

38.3 |

48.7 |

58.9 |

57.4 |

63.6 |

| Sheet |

1.1 |

5.2 |

11.5 |

23.4 |

37.5 |

45.6 |

50 |

54.6 |

| Bottle |

0.8 |

0.2 |

0.2 |

0.3 |

0.4 |

0.6 |

11.3 |

23.3 |

| Molding |

0.4 |

1.3 |

2.5 |

3.8 |

5.3 |

5.3 |

3.9 |

4.2 |

| Others |

0 |

0.3 |

0.3 |

2.7 |

3 |

2 |

1.6 |

2 |

| Total |

8.4 |

23.9 |

39.6 |

68.6 |

94.9 |

112.5 |

124.3 |

147.7 |

There is summation data by Japan Containers and Packaging Recycling Association,

although these values do not accurately reflect total market size in Japan. |

|

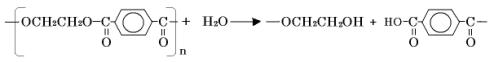

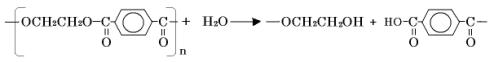

Problem with recycling PET

In molding recycling PET, hydrolysis that may reduce the molecular weight

is an unavoidable action when strictly controlling water. Hydrolysis of

Recycling PET proceeds according to the following structure.

|

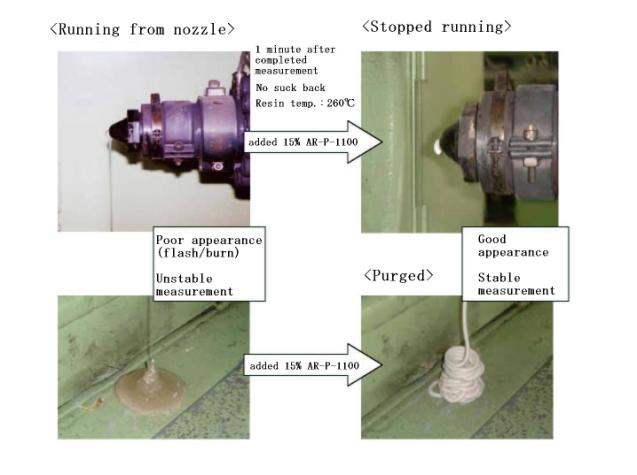

Such molecular weight reduction of recycling PET is the prime cause of

a decrease in impact strength of a molded part without drawing process.

And a decrease in the melt viscosity leads to running from nozzle and defective

appearance in injection molding, and makes it difficult to be diluted for

size enlargement in profile extrusion molding.

In order to solve these problems, we have developed and commercialized

"AR-P-1100", recycling PET modifier, making use of the technology

of styrene copolymer.

Recycling PET modifier AR-P-1100

AR-P-1100 may inhibit hydrolysis of recycling PET in molding to forcefully

make it high molecules. Such main problems in using recycling PET as the

decrease in impact strength and melt viscosity can be solved by adding

a little amount of AR-P-1100. Recycling PET is modified by AR-P-1100 where

elastic elements are uniformly dispersed in reactive parts so that they

are polymerized. Interfacial adhesion between recycling PET and elastomer

is reinforced, and impact strength is improved since elastic particles

restrain crack spreading that likely to occur continuously and in laminae.

AR-P-1100 improves the melt viscosity of recycling PET, of which modification

is entwinement between recycling PET and high-molecule-weight elastomers

that are scattered in molecular chains being steric by graft polymerization

in straight chains with reactive parts.

Additionally, AP-P-1100 is resistant to heat that can be blended with recycling

PET and dried together without melting and softening.

General features and characteristics of AR-P-1100 are described as follows.

Table 3. Physical properties

| Items |

Test method |

Unit |

AR-P-1100 |

| Hardness |

JIS K 7215 D |

-- |

39 |

| Specific gravity |

JIS K 7112 |

-- |

0.9 |

| MFR |

JIS K 7210 (8) |

g/10 min. |

1.8 |

| Tensile strength |

JIS K 6251 |

MPa |

7.2 |

| 100% modulus |

JIS K 6251 |

MPa |

7 |

| Elongation |

JIS K 6251 |

% |

160 |

| Tear strength |

JIS K 6252 |

KN/m |

69.6 |

* MFR (8) 200 - 5,000g

Note) values are represented for your information without guarantee |

|

Table 4. Effect to recycling PET

Recycling PET

AR-P-1000 |

100% |

95% |

90% |

85% |

| @ |

5% |

10% |

15% |

|

|

|

|

|

|

| Tensile yield strength (JIS K7113) |

Mpa |

61 |

55 |

49 |

46 |

| Bending strength (JIS K7203) |

Mpa |

81 |

72 |

65 |

58 |

| Bending elastic modulus (JIS K7203) |

Mpa |

2160 |

1950 |

1770 |

1670 |

| Notich Izod impact strength |

kJ/m2 (23) |

1.4 |

3 |

5.1 |

5.3 |

| (JIS K-7110) |

kJ/m2 (-10) |

1.2 |

3.2 |

5.2 |

5.2 |

| Melt viscosity (shear rate 12.2 sec -1)@ |

Pa.s |

210 |

720 |

1460 |

2150 |

| (shear rate 2430 sec -1)@ |

Pa.s |

95 |

130 |

110 |

110 |

Note) values are represented for your information without guarantee

Test condition:

sample made by injection molding; barrel temperature at 260; full flight

screw; die temperature at 30; predrying at 150 for 4 hours; test methods

conforming to JIS; melt viscosity measured by Capillary Rheometer at temperature

of 270; dice with 1 dia. X 10 mm t.; preheating time for 300 sec. |

|

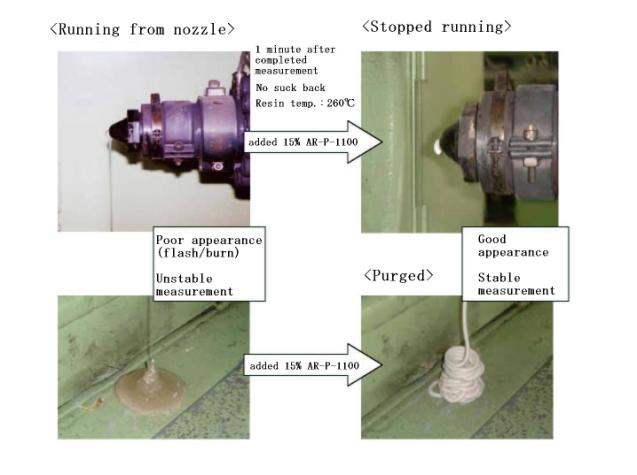

The table 4 shows the effect of AR-P-1100 to physical properties of recycling

PET. Izod impact strength was markedly improved by adding a little amount

of AR-P-1100. Besides, molded part preserved low-temperature impact strength

inherent in PET and offered beautiful surface luster. Tensile yield strength,

bending strength, and bend elastic modulus inclined to decrease. However,

it can compete with general-purpose olefin in those values. Melt viscosity

was also improved dramatically in the lower shear rates, that can prevent

running from nozzle in injection molding, minimize inhaling of the air

caused by suck back, consequently prevent such defective molding as flash,

and stabilize measurement accuracy.

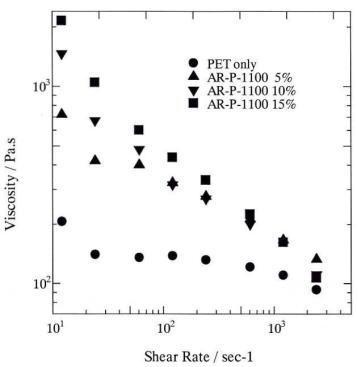

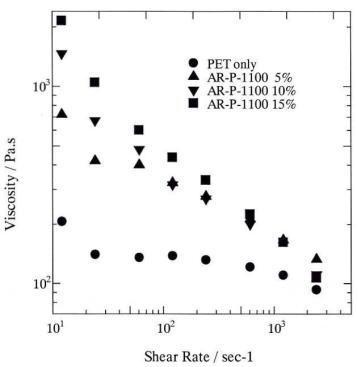

The improvement of melt viscosity by AR-P-1100 is also effective in extrusion

molding. The graph 1 shows the correlation between shear rates and melt

viscosity. By adding AR-P-1100 to recycling PET, the resin was viscous

enough in lower shear rates to be applicable to profile extrusion molding,

and became unsticky in higher shear rates mostly equivalent to pure recycling

PET.

AR-P-1100 makes recycling PET possible to be used in various molding methods

including injection and extrusion, producing such variation of melt viscosity

depending on shear rates.

Graph 1. Correlation between shear rate and viscosity of recycling PET

including AR-P-1100

Dice diameter : 1 mm

Test temp. : 270

Pre-heating time : 300 sec.

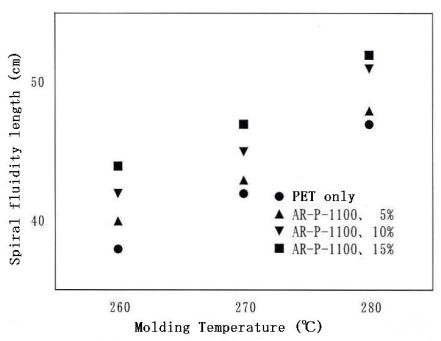

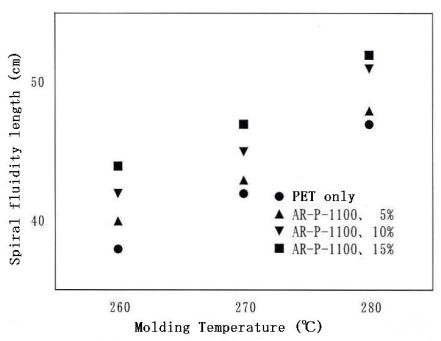

Graph 2. Spiral fluidity of recycling PET including AR-P-1100

@ @

Injection pressure : 100 Mpa

Mold : 4 mm W x 3 mm T |

Viscosity improvement of recycling PET, one of function of AR-P-1100, represents

viscosity variation depending on shear rates. The resin with such varying

viscosity may flow well in injection molding. The graph 2 shows spiral

fluidity of recycling PET in case of adding AR-P-1100. The fluidity of

recycling PET including 10 - 15% AR-P-1100 is nearly equivalent to that

of recycling PET only when raising molding temperature by 10. This suggests

that not only modified recycling PET is versatile in a wide range of molding

conditions, but also it may retard heat degradation and hydrolysis of recycling

PET by setting a lower molding temperature.

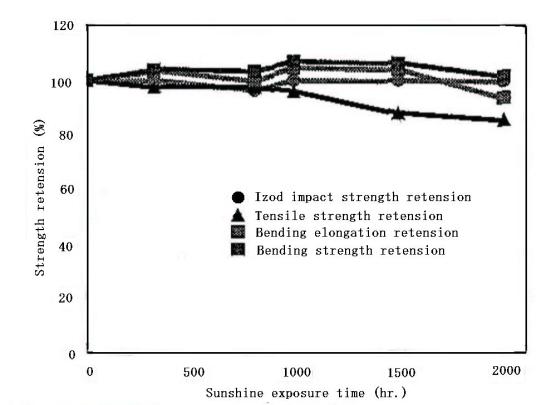

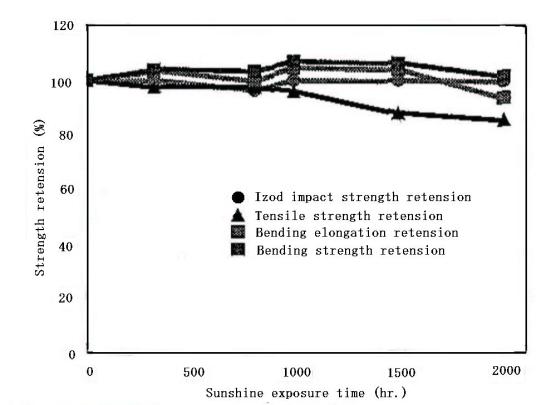

Graph 3. Weatherability of finished product containing 15% AR-P-1100

|

Tester : Suga Instrument's due cycle sunshine super long-life weather meter

WEL-SUN-DC

Test method : Continuous exposure test

| Test conditions |

: Black panel (BP) temperature at 63 } 3

@Light source by sunshine carbon arc lamp

@Spray cycle by 18/120 min

|

Precaution

(1) AR-P-1100 requires no predrying

(2) Recycling PET tends to be muddy in milky white by

adding AR-P-1100.

Image 1. Viscosity improvement of recycling PET by adding AR-P-1100

|

About PET resin

Modification of recycling PET achieved by AR-P-1100 may be materialized

by grasping characteristics of PET resin under optimum molding conditions.

Characteristics of PET resin in injection and extrusion molding are described

herein for your information.

PET main features are:

(1) The characteristics of PET resin may be influenced

by degree of crystallinity

(2) Requires a high molding temperature since the melting

point is 255

(3) May be degraded by progress of hydrolysis (heating)

(4) Requires strict water control (preliminary drying

at 130 - 140 for 3 - 4 hours)

Regarding (1), Change in its characteristics is shown in the table 5.

Table 5. PET resin characteristics depending on crystallinity

| @@ |

Crystallized |

Uncrystallized |

| Impact strength |

Very weak |

Weak |

| Rigidity |

Very strong |

Strong |

| Heat resistance |

Very strong |

Same as normal olefin |

| Appearance |

White |

Transparent |

|

As aforementioned, recycling PET is very weak in impact strength. Therefore,

it is preferable to make a molded part with recycling PET before crystallizing.

In order to keep recycling PET uncrystallized while molding, it is necessary

to design a molded part with even radial thickness of 2 mm or less, and

to keep die temperature as low as possible and rapidly cool it.

Besides, it is important in injection molding to raise injection speed

as high as possible. Desirable mold structure is direct gate type with

a high taper rate with which such demerits of recycling PET as a short

gate seal time and a low shrinkage may be counterbalanced.

Because of characteristics described as (2) and (3), it is preferable that

molding should be carried out at a temperature around 255 with a shorter

residence time.

According to the above (4), it is necessary in injection molding to dry

recycling PET preliminarily by a dryer. On the contrary, it is confirmed

through actual equipment that by adding AR-P-1100, preliminary drying may

not be needed in profile extrusion molding. Though it involves a few limitations

including the need for a molding machine equipped with a vent (pressure

reduction and suction devices are not needed), AR-P-1100 may satisfy such

users' needs when newly introducing recycling PET as the reduction of the

total running cost and unnecessity of introducing a new machine.

PET resin is versatile because of its inherent properties in luster, impact

strength at low temperatures, chemical resistance, absence from toxicity,

and wheatherability. It is desired that AR-P-1100 may contribute to the

wide use of recycling PET.

Appendix

DESIRABLE MOLDING CONDITIONS IN USING OF RECYCLING PET WITH AR-P-1100

(1) DESIRABLE CONDITIONS OF INJECTION MOLDING

Preparation

Predrying:

Drying Temp. at 130 ` 140, Time for 3 ` 5 hours

Any of dryer equipped with a dehumidifier (or an agitator) is preferable

In case of a chamber dryer, thickness of material on the pats (plate containers)

of dryer should be 30 mm or so.

Molding conditions

Temperature:

Barrel temp. between 225 and 260; nozzle temp. 10 higher than barrel

temp.

Feed zone should be set as low as possible.

e.g., C1 at 150; C2 at 200; C3 at 260; C4 at 260; N at 270

In raising the temperature at feed zone, it is possible to measure incorrectly

since resin may become soft before screw, and adhere to the barrel.

Maximum molding temperature should be 280. In a high temperature exceeding

such maximum temperature, resin may be physically degraded as yellowing

or decomposing.

Plasticization and injection conditions:

Back-up pressure: set lower (between 2 and 10 kg/cm2)

Revolution: set faster (about 100 rpm) in order to minimize resin unevenness

by residence time difference; it is preferable to postpone measurement

in accordance with cooling time.

Suck back: minimize running from nozzle

Injection speed: set as fast as possible in order to minimize defects of

finished product

Injection pressure: set higher in accordance with injection speed

Follow-up pressure: same pressure as general-purpose PET; pressure keeping

time should be re-set for every mold according to gate diameter and shape;

since PET may become a gate seal soon, it is hard to release molded parts

from the mold if pressure keeping time is too long.

Screw type: general-purpose or full flight type screw is sufficient; a

check ring (chuck ring) is needed.

Other notes: it is preferable to cool nozzle down to prevent cold slag,

and to withdraw nozzle every batch to prevent die from heating.

Mold:

Mold temperature: below 40; it is preferable to use a chiller to cool

die down so that impact strength of molded part may be improved

Cooling time: roughly same time as PVC

Other notes (for your information)

Preferable gate type is a direct gate with a taper of about 3 degrees.

Ideally, the gate length should be shorter in order not to make a large

gate diameter. Part strength near the gate may be poor or break-off may

occur If the gate diameter is too large. Using a direct gate, it is possible

to carry out molding smoothly.

L/t is limited by 250. In using general-purpose resin, L/t is extended

by raising molding and die temperature. In using PET, however, such temperature

control may result in vain. It is better to recondition hardware including

gate replacement.

(2) DESIRABLE CONDITIONS OF EXTRUSION MOLDING

Preparation

Predrying: basically it is unnecessary to predry. However, predrying at

140 may improve a little viscosity of resin and impact strength of molded

part.

Molding conditions

Temperature:

Barrel temp. between 230 and 270; In a vent type machine, raise temperature

before vent to accelerate exhaustion, so that physical properties of resin

may be improved.

It is easy to size in a lower adapter and dies

e.g., C1 at 230; C2 at 250; C3 at 265; C4 at 260; AD at 250; D at

240

In starting up, adapter and dies temperature should be 260, and lower

it gradually; If set as the above example from the beginning, it is possible

to raise back-up pressure rapidly.

Maximum molding temperature should be 280. In a high temperature exceeding

such maximum temperature, resin may be physically degraded as yellowing

or decomposing.

Revolution: set revolution as fast as possible (about 100 rpm) in order

to minimize degradation of physical properties of resin for a long residence

time.

Machine specification:

A vent type machine equipped with a vent and 2 shafts is preferable. When

using a machine with one shaft without vent, back-up pressure should be

higher by inserting a mesh.

Screw: L/D = 25 to 30; a screw with high kneading disc is preferable, although

a general-purpose screw design can be used.

|

@

@