PFOA-PFOS-free fluorinated water repellent and super oil repellent agent

PARAGUARD TO-8 / TON-8 / TOS-8 |

Super oil repellent finish as well as excellent water repellent finish

may be materialized by using PARAGUARD TO-8 in combination with PARAGUARD TON-8 or TOS-8.

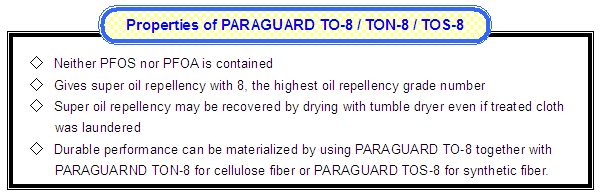

PARAGUARD TO-8 / TON-8 / TOS-8 are two-component fluorinated water and oil repellent agent which contain

neither PFOS nor PFOA. PARAGUARD TO-8 is used for cellulose fiber in combination with PARAGUARD TON-8 and for synthetic fiber with PARAGUARD TOS-8.

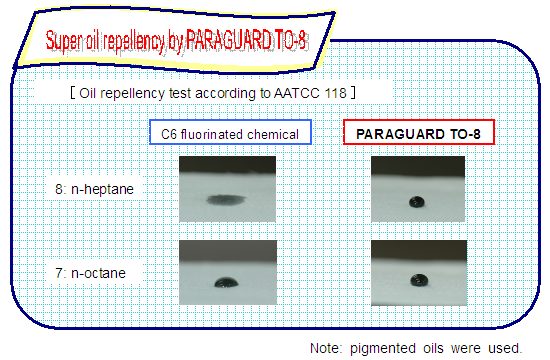

Newly developed PARAGUARD TO-8 / TON-8 / TOS-8 materialize super oil repellency

with 8, the highest oil repellency grade. And even if treated cloth laundered

several times, durable performance may be offered by drying with tumble

dryer.

| |

PARAGUARD |

| TO-8 |

TON-8 |

TOS-8 |

| Appearance |

Milky white emulsion |

Pale yellowish white

emulsion |

Pale yellowish white

emulsion |

| Ionic status |

Weak cationic |

Weak cationic |

Weak cationic |

| pH |

4.5 ± 2.0 |

3.0 ± 2.0 |

3.0 ± 2.0 |

| |

Cellulose fiber |

Synthetic fiber |

| Dosage |

PARAGUARD TO-8 |

1% soln. |

0.6% soln. |

| PARAGUARD TON-8 |

4% soln. |

|

| PARAGUARD TOS-8 |

|

2.4% soln. |

| Crosslinking agent |

1〜2% soln. |

|

| Melamine resin |

|

0.3% soln. |

| Catalyst |

|

0.1% soln. |

| Conditions |

Padding → Drying → Curing at 160 deg. C x 2 min.

(Dosage and conditions may vary depending on performance target, type of

fabric, and chemicals to be used together) |

Note: standard ratio between PARAGUARD TO-8 and TON-8 (or TOS-8) is 1 :

4

[ Process conditions ]

| |

% soln. |

|

padding |

| |

Pickup |

|

100% cotton broad: 76% polyester/cotton (65/35) broad : 71% |

| |

|

|

100% polyester chine cloth: 96% 100% nylon taffeta: 90% |

| |

Drying |

|

110 deg.C × 2 min. Curing 160 deg.C × 2 min. |

[ Test method ]

|

| Water repellency |

: JIS L-1092 spray method |

| Oil repellency |

: AATCC-118 |

| Laundering |

: JIS L-0217 103 |

|

○ Performance of PARAGUARD TO-8

| |

Cotton |

Polyester/cotton |

Polyester |

Nylon |

| PARAGUARD TO-8 |

4 |

5 |

3 |

4 |

1 |

2 |

3 |

4.5 |

| PARACAT PGE |

1 |

1 |

1 |

1 |

|

|

|

|

| Melamine resin |

|

|

|

|

0.3 |

0.3 |

0.3 |

0.3 |

| Catalyst |

|

|

|

|

0.1 |

0.1 |

0.1 |

0.1 |

Oil

repellency

(grade) |

Initial |

6-7 |

8 |

7-8 |

8 |

7-8 |

8 |

7-8 |

8 |

| L-10 air dry |

2-3 |

2-3 |

0 |

2-3 |

5 |

5 |

2-3 |

2-3 |

| L-10 tumble |

6-7 |

7 |

6 |

6-7 |

7 |

7-8 |

6 |

7 |

| L-20 air dry |

0-2 |

0-2 |

0 |

0 |

0 |

0 |

0-2 |

0-2 |

| L-20 tumble |

5-6 |

6-7 |

5-6 |

6 |

6 |

6 |

6 |

7 |

| L-30 air dry |

0-2 |

0-2 |

0 |

0 |

0 |

0 |

0-2 |

0-2 |

| L-30 tumble |

5 |

6-7 |

5 |

5-6 |

6 |

6 |

6 |

7 |

Water

repellency

(grade) |

Initial |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

| L-10 air dry |

2-3 |

3 |

2-3 |

2-3 |

2-3 |

3 |

3-4 |

3-4 |

| L-10 tumble |

3-4 |

4 |

3-4 |

4 |

4 |

5 |

4-5 |

4-5 |

| L-20 air dry |

2 |

2 |

2-3 |

2-3 |

2 |

2-3 |

2 |

2 |

| L-20 tumble |

3 |

3-4 |

3-4 |

3-4 |

4 |

5 |

4 |

4 |

| L-30 air dry |

1-2 |

2 |

1-2 |

1-2 |

2 |

2-3 |

2 |

2 |

| L-30 tumble |

2-3 |

2-3 |

3 |

3 |

3-4 |

4-5 |

3-4 |

3-4 |

○ Performance of PARAGUARD TO-8 with TON-8/TOS-8

| |

Cotton |

Polyester/cotton |

Polyester |

Nylon |

| PARAGUARD TO-8 |

1 |

1 |

0.6 |

0.6 |

| PARAGUARD TON-8 |

4 |

4 |

|

|

| PARAGUARD TOS-8 |

|

|

2.4 |

2.4 |

| PARACAT PGE |

1 |

1 |

|

|

| Melamine resin |

|

|

0.3 |

0.3 |

| Catalyst |

|

|

0.1 |

0.1 |

Oil

repellency

(grade) |

Initial |

7-8 |

8 |

8 |

7-8 |

| L-10 air dry |

6 |

6 |

7-8 |

6 |

| L-20 air dry/tumble |

6/6-7 |

5-6/6 |

6-7/8 |

6/6-7 |

| L-30 air dry/tumble |

6/6-7 |

5-6/5-6 |

6/7-8 |

6/6-7 |

Water

repellency

(grade) |

Initial |

5 |

5 |

5 |

5 |

| L-10 air dry |

4 |

4 |

5 |

4-5 |

| L-20 air dry/tumble |

3-4/4-5 |

3/4-5 |

4-5/5 |

4/5 |

| L-30 air dry/tumble |

3/3-4 |

3/4 |

4-5/5 |

4/4-5 |

|

|

Preliminary test should be carried out to check performance. Particularly,

performance might deteriorate with cotton dyed cloth in which fixing agent

is likely to remain. |

|

|

In order to avoid quality deterioration, the container should be closed

airtightly and stored at cool dark place. |

|

|

Prevent the product from being in contact with PFOA or PFOS containing

chemical. |

| The information herein offered is based on the best of our knowledge at

present. However, we are not able to guarantee these matters, as the result

of application may vary according to conditions adopted. Preliminary tests

are, therefore, recommended in all cases. Please refer to MSDS regarding

handling of the products. |

(C) copyright 2011 Venture Chemical Ltd.All Right Reserved. |

|