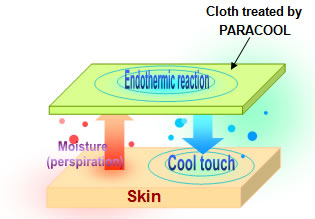

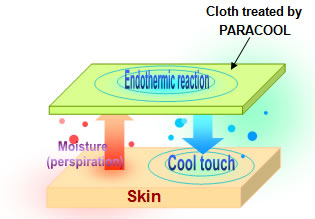

PARACOOL IDA and IDA-2 are mainly composed of erythritol and xylitol which have a strong cooling

effect (endothermic reaction) when they dissolve in water. By applying

PARACOOL IDA or IDA-2 to textile apparels, wearers may feel coolness as a result of endothermic

reaction of such sugar alcohol as erythritol and xylitol in contact with

insensible perspiration and sweat.

PARACOOL IDA and IDA-2 are special emulsion of coated particles enclosing water soluble erythritol

and xylitol. The emulsion is characterized by its nanometer-sized particles

and extreme permeability which provides superior washability.

PARACOOL IDA is applied for cotton, polyester/cotton (E/C), nylon and the like. On

the other hands, PARACOOL IDA-2 is specialized for 100% polyester cloth.

| |

PARACOOL IDA |

PARACOOL IDA-2 |

| Ionic status |

Nonionic |

| pH |

5.0 ± 1.0 |

| Appearance |

Transparent emulsion |

| Solubility |

Easily soluble in water |

| |

PARACOOL IDA |

PARACOOL IDA-2 |

| Subject material |

Cotton, E/C, Nylon, etc. |

100% polyester |

| Water absorbency |

Good |

Superior |

| Binder to be co-used |

PARACOOL IDC-1 or IDC-6 |

PARACOOL IDC-6 |

| 1. |

|

PARACOOL IDA is applied for cotton, polyester/cotton (E/C), nylon and the like. On

the other hands, PARACOOL IDA-2 is specialized for 100% polyester cloth. |

| 2. |

|

“Cool touch” can be given to cloth as well as water absorbency. |

| 3. |

|

Softness can be given without stiffness. |

| 4. |

|

Excellent workability is due to its superior solubility to water. |

| 5. |

|

Curing process can be applied in accordance with necessary conditions for

substrate. |

| 6. |

|

It has dilution stability and compatibility with other chemicals. |

|

PARACOOL IDA or IDA-2 is applied in padding process

Standard dosage and process:

| |

For Cotton, E/C, Nylon, etc. |

For 100% polyester |

| Isolated use |

PARACOOL IDA |

50~100g/ℓ |

PARACOOL IDA-2 |

50~100g/ℓ |

| With binder |

PARACOOL IDA

PARACOOL IDC-6* |

50~100g/ℓ

20~40g/ℓ |

PARACOOL IDA-2

PARACOOL IDC-6 |

50~100g/ℓ

20~40g/ℓ |

* If a cationic chemical is used concurrently, alternatively nonionic binder

PARACOOL IDC-1 is available.

Cooling Effect Evaluation

PARACOOL IDA for cotton, E/C and nylon cloth:

| |

1 |

2 |

| PARACOOL IDA |

Blank

(water) |

5 |

| PARACOOL IDC-6 |

2 |

Water absorbency

(sec.) |

Cotton

broad |

Initial |

3~4 |

2 |

| HL-20 |

― |

2 |

| E/C broad |

Initial |

19.0 |

3 |

| HL-20 |

― |

3 |

Nylon

knitted |

Initial |

1.0 |

1~2 |

| HL-20 |

7.0 |

5.0 |

Cooling effect

(℃) |

Cotton

broad |

Initial |

― |

-2.3 |

| HL-20 |

― |

-1.8 |

| E/C broad |

Initial |

― |

-2.1 |

| HL-20 |

― |

-1.6 |

Nylon

knitted |

Initial |

― |

-1.7 |

| HL-20 |

― |

-1.2 |

PARACOOL IDA-2 for 100% polyester cloth:

| |

1 |

2 |

| PARACOOL IDA-2 |

Blank

(water) |

5 |

| PARACOOL IDC-6 |

2 |

Water absorbency

(sec.) |

Initial |

1.0 |

1.0 |

| HL-20 |

180 or more |

1.0 |

Cooling effect *

(℃) |

Initial |

― |

-3.8 |

| HL-20 |

― |

-3.6 |

* Maximum temperature difference in comparing with blank solution

Condition: Dipping → Nipping → Drying (110ºC x 3 min.) → Curing (160ºC

x 1 min.)

Note: Binder (PARACOOL IDC-6 or alternatively PARACOOL IDC-1) should be

used together for polyester fiber. Otherwise yellowing may occur by curing

process.

| What is cool touch finish? |

Cool touch finish does not mean textile finishing to make “good looking

in appearance” is this context, but provides cool handling touch realized

by using fiber material that offers cool handle by itself and/or a special

chemical agent to give cooling effect.

Cool touch by application of heat transfer is usually produced by chemical agent mainly composed of phase-change

material (PCM) which may help heat transfer from human body to treated

cloth. There is instant coolness when contacting skin to the cloth. However,

there might be hot and humid sensation when keeping in contact because

treated cloth tends to be less permeable.

|

On the contrary, cool touch by endothermic reaction is produced by PARACOOL IDA and IDA-2 mainly composed of erythritol and xylitol which may absorb heat while

dissolving in water (moisture and perspiration of the body in this context).

There is moderate coolness and comfort while wearing cloth treated by PARACOOL IDA or IDA-2, absorbing moisture (perspiration) of the body. |

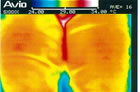

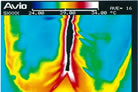

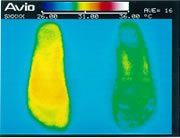

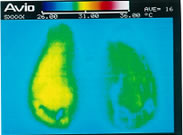

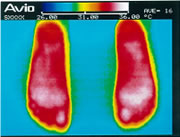

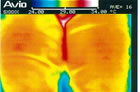

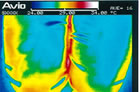

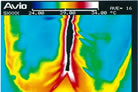

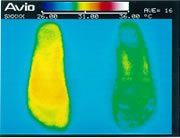

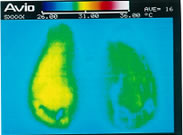

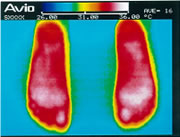

A hand was placed on sample cloth for 3 minutes. And thermographic image

was observed a minute later.

Blank cloth

|

|

|

Treated by PARACOOL IDA

|

|

| |

|

Heat of solution |

| ubstance |

Heat of solution

(cal/g) |

| Xylitol |

-34.8 |

| Sorbitol |

-24.1 |

| Glucose |

-13.8 |

| Lactose |

-12.6 |

| Sucrose |

-4.5 |

| Erythritol |

-42.9 |

|

|

|

Heat of solution: the energy required to dissolve one gram of the substance

Heat of solution of xylitol: - 34.8 cal/g

1 calorie is the heat to raise 1 gram of water by 1 degree Celsius

1 gram of xylitol may lower the temperature of 10 grams of water 3.48

degree Celsius

| Before adding xylitol |

| Water temp.: 28.7℃ |

|

|

|

| |

| After dissolved xylitol |

| Without xylitol : 28.3℃ |

| With xylitol : 23.1℃ |

|

| 1. |

|

Preliminary tests should be carried out to check the effect to handling

touch and color fastness as well as compatibility with other chemicals. |

| 2. |

|

Finished cloth should be packed in dry state. If it is packed in wet state

(soon after pressing a steam iron), it might be whitened. |

| 3. |

|

The product is stable under normal condition. It is ideal to store it at

cool (temperatures between 5 and 35ºC) dark place. |

|

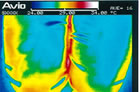

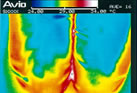

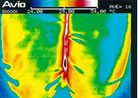

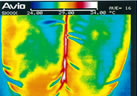

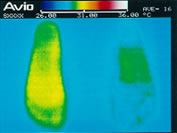

Thermographic image: visible denim pants sustainable cool feeling effect

performed with PARACOOL IDA |

〔 Summary 〕

| 1. |

|

Sustainability of cool feeling effect (repeating cool feeling effect by

every perspiration one shed) of denim pants treated by PARACOOL IDA is

measured via thermography. |

| 2. |

|

In comparing to untreated part, treated part offers a lower temperature

which is due to endothermic reaction by spraying water as virtual perspiration. |

| 3. |

|

5 minutes later after sprayed, treated part still offers a lower temperature

while untreated part reverts to or may be heated more than initial state

as the result of hydration heat of cotton fiber. And the same result is

available when repeating the process three times. |

| 4. |

|

The result shows that cloth treated by PARACOOL IDA gives sustainable cool

feeling effect which may |

|

〔 Test materials 〕

| Specimen |

|

:Denim pants consisting of blank and cool feeling finish |

| Left) |

|

Blank |

| Right) |

|

10% soln. PARACOOL IDA & 6% soln. PARACOOL ID-6

Padding→ Drying (110ºC x 3 min.)→ Curing (160ºC x 2 min.) |

|

〔 Test method 〕

| 1. |

|

Specimen is worn by subject for 5 minutes to stabilize surface temperature. |

| 2. |

|

Water is sprayed on the thigh parts (to simulate perspiration to give moisture). |

| 3. |

|

The variation in thermograph is monitored right after sprayed, 1 minute

later and 5 minutes later.

Note: Subject is seated as the specimen closely contacts the thigh parts,

so that the body temperature may be transmitted to specimen. Thermographic

image at the thigh parts is taken at specified intervals. |

| 4. |

|

Repeat the above 1 to 3 at least twice.

[Hygrothermal condition: 23 - 25 ºC / 40 – 50%] |

|

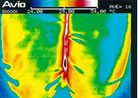

〔 Evaluation of sustainable cool feeling effect via thermography 〕

| |

First |

Second |

Third |

| |

Blank |

Treated |

Blank |

Treated |

Blank |

Treated |

Before spray

(5 minutes

later after

wearing) |

|

|

|

Right after

sprayed |

|

|

|

| 1 min. later |

|

|

|

| 5 min. later |

|

|

|

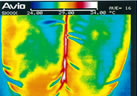

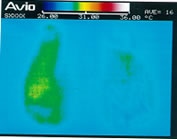

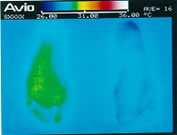

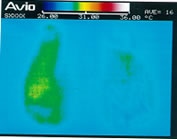

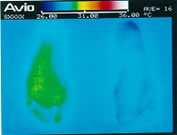

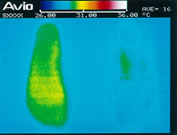

| Cooling effect (used infrared photography) |

[ Material ] 100% polyester dyed fabric(shoes insole, fabric)

[ Testing recipe ]

| |

1 |

2 |

| PARACOOL IDA-2 |

10% |

20% |

| PARACOOL IDC-6 |

4% |

4% |

[ Process & Conditions ]

For fabric:

Recipe: No1, 2

Process : Padding method, Pick up: 78%, Dry: 110℃×4min

For insole

Recipe: No.2

Hand spray (quantity for application 210g/㎡) → Dry : 110℃ × 30min.

The amount of processing agent adhesion of hand spray was same as Pad processing

(Pick up85%).

Surface thermometry by infrared photography

[ Test Method ]

| 1. |

|

Put feet on test samples for a minute. |

| 2. |

|

Take infrared photographies after remove feet immediately.

Similarly, take two more when a minute later, and 2minutes later. |

|

Surface thermometry (use infrared photography)

[ Material ] Your cloths

[ Testing recipe ] Recipe: No1 IDA-2 / IDC-6、10% / 4%

| |

Infrared photography |

Appearance |

| |

Non treated |

Treated |

Put feet on test samples

for three minutes. |

|

|

Immediately

After remove feet |

|

|

| 20second later |

|

| 1minute later |

|

| 2minutes later |

|

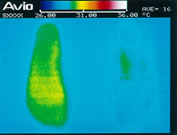

Surface thermometry (use infrared photography)

[ Material ] Your cloths

[ Testing recipe ] Recipe: No2 IDA-2 / IDC-6、20% / 4%

| |

Infrared photography |

Appearance |

| |

Non treated |

Treated |

Put feet on test samples

for three minutes. |

|

|

Immediately

After remove feet |

|

|

| 20second later |

|

| 1minute later |

|

| 2minutes later |

|

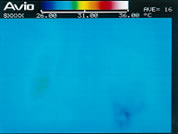

Surface thermometry (use infrared photography)

[ Material ] Your cloths (Shoe insoles)

[ Testing recipe ] Recipe: No2 IDA-2 / IDC-6、20% / 4%

| |

Infrared photography |

Appearance |

| |

Non treated |

Treated |

Put feet on test samples

for three minutes. |

|

|

Immediately

After remove feet |

|

|

| 20second later |

|

| 1minute later |

|

| 2minutes later |

|

| The information herein offered is based on the best of our knowledge at

present. However, we are not obliged to guarantee the matter, as the result

of application may vary depending on conditions adopted. Preliminary tests

are, therefore, recommended in all cases. Please refer to MSDS regarding

handling of the products. |

(C) copyright 2014 Venture Chemical Ltd.All Right Reserved. |

|