In the 21st Century, businesses must be able to deal effectively with environmental issues. Lowering BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand) and chromaticity values and raising clarity levels through the Water Quality Pollution Control Act and local effluent regulations has become critical. As a result, existing dye works combine activated sludge and coagulation/settling treatments and emit 20-50 tons of sludge per day to treat 2000-5000 tons of drainage water per day in order to pump in large quantities of ferrous chloride and aluminum hydroxide for decolourization. The generation of large quantities of sludge increases labor and sludge disposal costs. There's also the major challenge of finding an ultimate disposal site for the sludge in the future. Existing methods illustrate the need for treatment methods that reduce the amount of chemical and sludge waste. This treatment system decolorizes azo dye wastewater through the use microorganisms. By combining microbial and activated sludge treatments, the system achieves lower COD and BOD values, reduces waste sludge emissions, and realizes more affordable running costs.

The technology has been developed through successful result of unique business project in terms of “Coloured Wastewater Bio-Decolourization System” sponsored and approved by Japan Science Technology Agency (JST). Specialty of the Bio-Decolourization System A species of microbes which may decompose azo dyes >>> Microbes of the system Microbe, existing everywhere on the earth and in living organisms, is a generic name of any organism which is too small to be viewed to the naked eye but may be viewed through a microscope. Among various species of microbes, bacillus, the same strains of natto yeast (to ferment soybeans), is used for the system as a dye degrading bacterium.

Microbes have been used traditionally for food processing such as yeast and aspergillus that ferment soybeans to make natto or soy sauce. In sewage, they have been used for activated sludge to reduce COD and BOD. >>> Enzyme It is true that the fermentation of soybeans to make soy sauce or fermented soybeans and the decomposition of azo dyes by using the system introduced herein are carried out by the same basic action of microbes: metabolism and enzymatic process. Enzymes are any of proteins which perform as catalysts to promote biochemical reaction in living organisms. Although they are silent by themselves, they offer catalytic reaction with organic substances. Thus, they are essential for living organisms including human body where many enzymes are used up in the metabolism and digestion. The one of significant features of enzymes is substrate specificity in which they are selective for their substrates. The Bio-Decolourization system introduces Bacillus OY1-2 producing enzymes which may select the azo group of azo dyes to transform them into colourless compounds. The enzyme of Bacillus OY1-2 is defined by International Union of Biochemistry and Molecular Biology (IUBMB). Its name,“azobenzene reductase” suggests an enzyme to reduce azo groups. The enzyme code: EC 1.7.1.6. IUBMB defines the characteristics of enzymes according to four-digit code. “1” on the first digit represents the enzyme that catalyses oxidation or reduction reactions “7” on the second digit represents nitrogenous compounds as electron donors “1” on the third digit means NADP and NADPH coenzymes as electron acceptors in the nitrogenous compounds defined by the above second digit “6” on the fourth digit means that the enzyme defined by the above three digits is azoreductase (azobenzene reductase) The four-digit code indicates that the enzyme reduces azo groups through oxidation and reduction reactions where NADP and NADPH perform as electron acceptors and donors. NADP and NADPH are known as coenzymes. Specifically, they are called coenzyme vitamins. Vitamin B6 and B12 are categorized as the same. Besides, niacin is another name of NADP and NADPH which are often contained in nutritious drinks. >>> Specialty of azoreductase, bio-decolourization enzyme in this system >>> Reduction of dyes (mechanism of de-colourization) By reacting azo bond N=N of azo dye (C.I. Acid Red 88) with azoreductase and NADPH coenzyme, azo dye may be reduced to be 1-naphthylamin-4-sodium sulfonate and 1-amino-2-naphthol. >>> Bacillus-supported substrate The importance of this system is enzymatic reaction of Bacillus OY1-2. The bacteria, however, might be swept away by discharging water because it is not nektonic. Although it is not pragmatical, sustaining a large number of the bacteria by raising BOD in drainage is ideal.

In order to prevent the bacteria from draining with discharging water and to stabilize the number of bacteria, this system introduces Bacillus-supported porous substrate in its bioreactor (reactor tank for decolourization) as shown in the following pictures. Besides, the system is equipped with culture tank that fill up the bacteria regularly to sustain the number of Bacillus OY1-2.

>>> De-colourization test with dye solutions We executed decolourization test with reactive dyes, disperse dyes, vat dyes and pigments to which Bacillus OY1-2 was added. Since it is known that decolourization performance by Bacillus OY1-2 is effectively encouraged under an anaerobic condition, the test result shown hereof is that came out under an anaerobic condition.

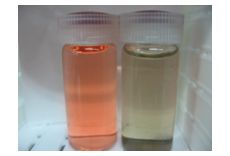

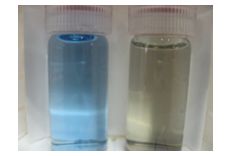

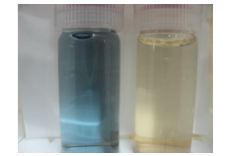

>>> De-colourization test with coloured waste water By collecting waste water of a dyeing plant which contaminated by several types of dyes, decolourization test was carried out with Bacillus OY1-2. The picture shows the result: blank (waste water sample) in the left side and decolourized sample in the right side.

The above graph indicates spectrophotometric measurement of coloured waste water and decolourized sample. As to decolourized sample, absorbency was decreased at all wavelengths. >>> De-colourization test on our experimental dyeing plant Specifications:

Graph 2 indicates the colouration of waste water and treated water of our experimental dyeing plant monitored from January to July 2008. (Measured values were obtained with samples containing suspended solids. Coloration might be raised if removed suspended solids). Decolourization was confirmed in this test.

Graph 3 shows spectrophotometric measurement for the samples obtains from our experimental dyeing plant. We confirmed decolourization of waste water. Additionally, we measured COD and BOD in this experiment.

Effective bio-filtration was realised since BOD and COD were reduced by less than 50 mg/l and 100 mg/l respectively. >>> Bio-decolourization system for dyeing plant

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||