Ultimate Charcoal Fibre

Made of Binchō-tan (white charcoal) powder with natural/synthetic fibre

|

| in Batting/Non-Woven Cloth Form |

|

|

C21 is commercially supplied in the form of batting and impregnated non-woven

cloth and sprayed non-woven cloth.

|

|

|

| in Spun/Filament Yarn Form |

|

|

C21NX is blended in polyester and the yarns are commercially available with

the following specifications:

70/30 cotton/polyester spun yarn in 30s or 40s counts 70/30 cotton/polyester spun yarn in 30s or 40s counts

100 % polyester filament (150 dtex) 100 % polyester filament (150 dtex)

100 % polyester staple fibre (6.7 dtex ü~ 51 mm) 100 % polyester staple fibre (6.7 dtex ü~ 51 mm) |

|

The ultimate charcoal fibre is human-friendly fibre to give comfort and

vital energy.

Keeping warm in winter, and keeping dry in summer Keeping warm in winter, and keeping dry in summer

Offering antibacterial and odour killing effect Offering antibacterial and odour killing effect

Wide range of application possibilities Wide range of application possibilities

Use:

For bedding materials For bedding materials

For garments For garments

For interior cloths For interior cloths

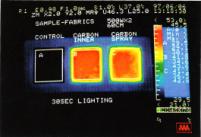

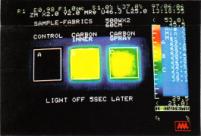

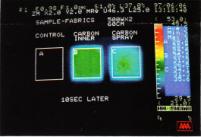

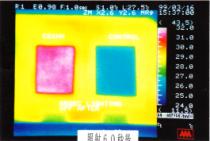

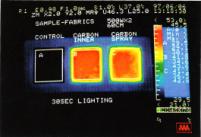

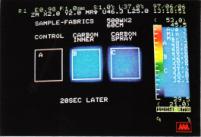

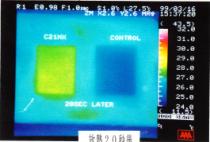

| Table 1. |

Thermal characteristics of C21 impregnated and spayed non-woven cloth

Thermal storage and release property by Infrared radiation exposure |

| Elapsed timeü@ |

ü@ü@ |

Measured temp. (üÄ)ü@ü@ |

Thermographic imageü@ |

| Blank |

Carbon

inner |

Carbon

spray |

30 sec.

After

exposureü@ |

Av. temp. |

29.5 |

41.8 |

41.1 |

|

| Min. temp. |

29.1 |

34.8 |

36.5 |

| Max. temp. |

30.1 |

43.6 |

42.8 |

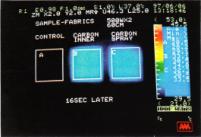

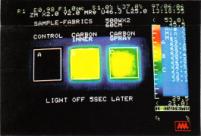

5 sec.

after

heat release |

Av. temp. |

29.1 |

38.5 |

37.3 |

|

| Min. temp. |

28.8 |

32.8 |

33.3 |

| Max. temp. |

29.7 |

39.6 |

39.1 |

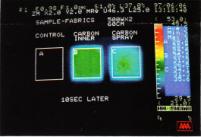

10 sec.

after

heat release |

Av. temp. |

28.8 |

35.2 |

34.1 |

|

| Min. temp. |

28.5 |

31.3 |

31.3 |

| Max. temp. |

29.5 |

36.5 |

35.6 |

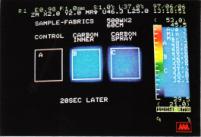

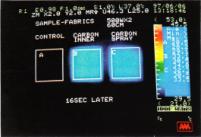

15 sec.

after

heat release |

Av. temp. |

28.5 |

33.1 |

32.3 |

|

| Min. temp. |

28.2 |

30.5 |

30.5 |

| Max. temp. |

29.1 |

34.0 |

33.5 |

20 sec.

after

heat release |

Av. temp. |

28.3 |

32.0 |

31.2 |

|

| Min. temp. |

28.0 |

30.0 |

30.0 |

| Max. temp. |

28.8 |

32.7 |

32.1 |

Table 2. Odour killing effect of C21

(1) Adsorbability on ammonia (initial concentration: 40 ppm)

| Sampleü@ |

Ammonia concentration (ppm) |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21 |

40 |

10 |

8 |

3 |

| Blank |

40 |

37 |

35 |

32 |

(2) Adsorbability on acetic acid (initial concentration: 100 ppm)

| Sampleü@ |

Acetic acid concentration (ppm)ü@ü@ü@ |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21 |

100 |

20 |

10 |

3 |

| Blank |

100 |

83 |

80 |

43 |

(3) Adsorbability on hydrogen sulfide (initial concentration: 15 ppm)

| Sampleü@ |

Hydrogen sulfide concentration (ppm)ü@ü@ü@ |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21 |

15 |

12 |

8 |

2 |

| Blank |

15 |

15 |

13 |

13 |

Test conditions:

3.0 g sample was put in sampling bag (Tedlar® bag), and 3 liters specified

gas with specified concentration was injected. Then, gas concentration

was determined with detecting tube 0.5 hour later and at intervals of 2

hours up to 24 hours. (Test conducted by Kaken Test Center)

Table 3. Antibacterial effect of C21

| Sampleü@ |

Antibacterial efficacy evaluated by change in number of bacteria

(against Staphylococcus aureus) |

| Increase-decrease rate |

Increase or decrease |

Difference between

increase and decrease |

| C21 |

1.0 ü~ 10-7 or less |

- 1.0 or less |

4.0 or more |

| Blank (*) |

1.0 ü~ 103 |

3.0 |

-- |

(*) 100 % nylon standard white cloth

Test conditions:

Having the bacteria suspended on sterile liquid bouillon, and 0.2 ml was

took (including about 430,000 bacteria) to inoculate on 0.2 g sample. Then

the number of bacteria was counted after cultured at 37üÄ for 18 hours.

(Test conducted by Kaken Test Center)

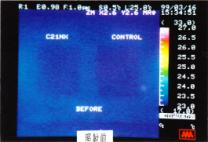

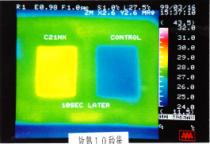

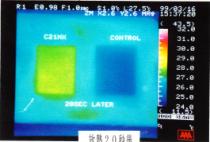

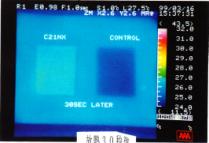

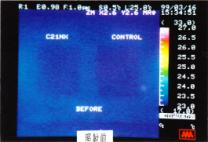

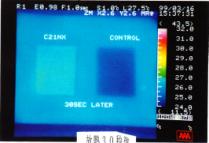

| Table 4. |

Thermal characteristics of C21NX (athletic supporter) |

|

Thermal storage and release property by Infrared radiation exposure |

Elapsed

timeü@ |

ü@ü@ |

Measured temp. (üÄ)ü@ |

Thermographic imageü@ |

| C21NX |

Control |

Before

exposureü@ |

Av. temp. |

23.1 |

23.0 |

|

| Min. temp. |

23.0 |

23.0 |

| Max. temp. |

23.3 |

23.2 |

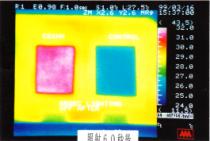

60 sec.

after

exposure |

Av. temp. |

31.2 |

26.0 |

|

| Min. temp. |

30.7 |

25.7 |

| Max. temp. |

31.7 |

26.7 |

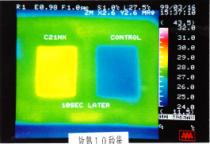

10 sec.

after

heat

release |

Av. temp. |

29.0 |

25.2 |

|

| Min. temp. |

28.6 |

25.0 |

| Max. temp. |

29.3 |

26.0 |

20 sec.

after

heat

release |

Av. temp. |

27.6 |

24.8 |

|

| Min. temp. |

27.3 |

24.6 |

| Max. temp. |

28.0 |

25.5 |

30 sec.

after

heat

release |

Av. temp. |

26.6 |

24.6 |

|

| Min. temp. |

26.3 |

24.3 |

| Max. temp. |

27.0 |

25.0 |

Table 5. Odour killing effect of C21NX

(4) Adsorbability on ammonia (initial concentration: 40 ppm)

| Sampleü@ |

Ammonia concentration (ppm)ü@ü@ü@ |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21NX |

40 |

37 |

33 |

17 |

| Blank |

40 |

39 |

38 |

26 |

(5) Adsorbability on acetic acid (initial concentration: 100 ppm)

| Sampleü@ |

Acetic acid concentration (ppm)ü@ü@ü@ |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21NX |

100 |

64 |

51 |

14 |

| Blank |

100 |

71 |

66 |

34 |

(6) Adsorbability on hydrogen sulfide (initial concentration: 15 ppm)

| Sampleü@ |

Hydrogen sulfide concentration (ppm)ü@ü@ü@ |

| Initial |

30 min. later |

2 hrs. later |

24 hrs. later |

| C21NX |

15 |

13 |

13 |

13 |

| Blank |

15 |

15 |

15 |

14 |

Test conditions:

1.0 g sample was put in sampling bag (Tedlar® bag), and 3 liters specified

gas with specified concentration was injected. Then, gas concentration

was determined with detecting tube 0.5 hour later and at intervals of 2

hours up to 24 hours. (Test conducted by Kaken Test Center)

Table 6. Antibacterial effect of C21NX

| Sampleü@ü@ |

Antibacterial efficacy

(against Staphylococcus aureus ATCC 6538P)ü@ü@ |

| Number of active bacteria |

Bacteriostatic activity |

Bactericidal activity |

| C21NX |

9.5 ü~ 103 |

3.9 |

1.5 |

Blank:

right after inoculated |

2.7 ü~ 104 |

--ü@ |

--ü@ |

Blank:

18 hours after inoculated |

8.4 ü~ 103 |

--ü@ |

--ü@ |

(*) 100 % nylon standard white cloth

Test conditions: JIS L 1902 (Test conducted by Kaken Test Center)

Specialty ofBinchō-tan

Binchō-tan or white charcoal is a traditional charcoal of Japan. It dates to the Edo period, when during

the Genroku era, a craftsman named Bitchū-ya Chōzaemon began

to produce it in Tanabe, Wakayama. The raw material is oak, specifically

ubame oak (Quercus phillyraeoides), which is designated as the official symbolic tree of Wakayama Prefecture.

Wakayama is the major production site of high-quality charcoal, and it

has designated the traditional production technique of Binchō-tan as an intangible cultural heritage

Traditional production process:

|

|

ü@ ü@ |

|

| ć@ Cut out raw woods (20 - 40 year-old Quercus phillyraeoides or Quercus

glauca) |

ćA Day 1st: put raw woods in the kiln |

ćB Day 2nd - 3rd: dry raw woods (vapoured with white smoke) |

ćC Day 4th - 6th: Keep firing the kiln |

|

|

|

ü@ |

| ćD Day 6th - 7th: after charred them, open the kiln gradually to introduce

air and burn bark so that they are glowing |

ćE Day 7th - 8th: put them out one by one carefully |

ćF Collect them on coal bed, and sprinkle powders of micronized coal on

them. |

ü@ |

Superior absorbability of Binchō-tan is due to its numerous small pores. Their superficial area per 1 gram

spans about 300 square meters. In spite of its sponge-like structure, Binchō-tan is harder than black charcoal, and rings with a metallic sound when struck.

Possible anticancer effect

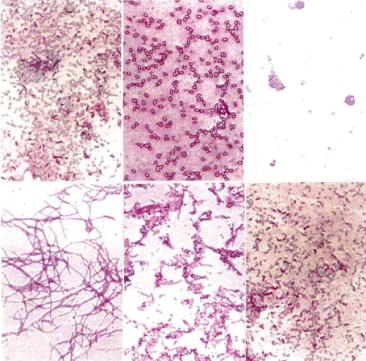

It has been discovered that some nameless species of bacteria exist in

Binchō-tan as shown in the following microscopic images dyed with phenosafranine

(10 ü~ 100 = 1000). (investigated by the national institute of advanced

industrial science and technology, Japan)

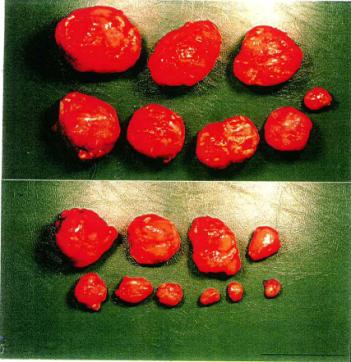

Experimentation to check any of effect of these bacteria on sarcoma was

carried out. The following pictures show a series of sarcomas in original

state (upper) and the same 28 days after these bacteria were injected to

them (lower). Shrunk sarcomas may suggest possible anticancer effect of

these bacteria.

(C) copyright 2011 Venture Chemical Ltd.All Right Reserved. |

|

ü@

ü@